| During the Shang and Zhou dynasties, China gave birth to "blue glazed porcelain" using porcelain clay as a substrate for high-temperature glaze, known as "primitive blue porcelain". At almost the same time, in West Asia and Persia, which did not produce porcelain clay, the "firing porcelain" technique of applying low-temperature glaze on metal bodies emerged. This porcelain firing technology is applied through low-temperature glaze, breaking the limitations of the original inlay in color and artistic effect, giving new vitality to ancient gold and silver inlay art, which is called "primitive porcelain firing". Later, it was introduced to China during the Tang and Song dynasties, and the Chinese people absorbed the manufacturing technology of this enamel ware, which was improved and carried forward several times. |

With the progress of the Industrial Revolution, through repeated research and transformation of traditional enamel techniques by modern craftsmen, decorative art enamel handicrafts that initially used gold, silver, and copper as matrix materials have been extended to practical industrial enamel materials that use steel and alloy as matrix materials, creating high-quality enamel architectural decoration products. As a combination of traditional culture and modern technology, enamel steel plates for architectural decoration have durable characteristics far superior to other metal decoration products, becoming a new generation of high-end architectural decoration products in the future. |  |

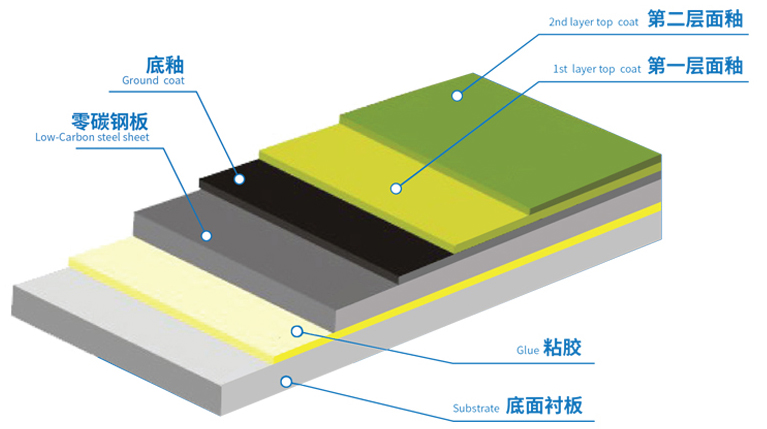

| Enamel steel plate is a composite material formed by combining high-quality steel plate and special functional inorganic non-metallic material through a new electrostatic dry powder coating process and high-temperature firing, which creates a strong chemical bond between the high-quality steel plate and special functional inorganic coating. Enamel steel plate - a new type of composite material made of inorganic glass material fused onto the steel plate and firmly bonded with it. |

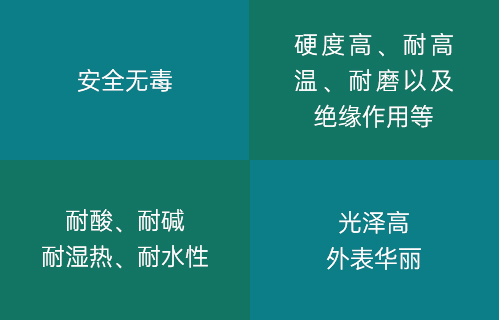

Characteristics of Enamel1. Hardness up to Mohs 6.0, higher than steel, lower than gemstones |  |

|  |

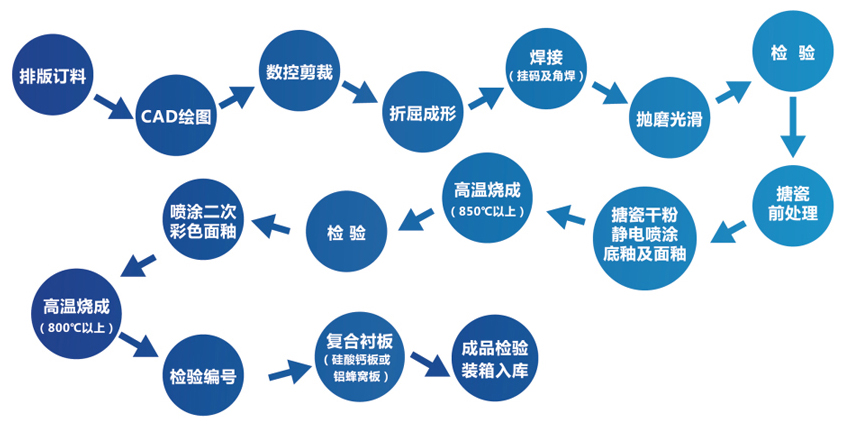

Technological process

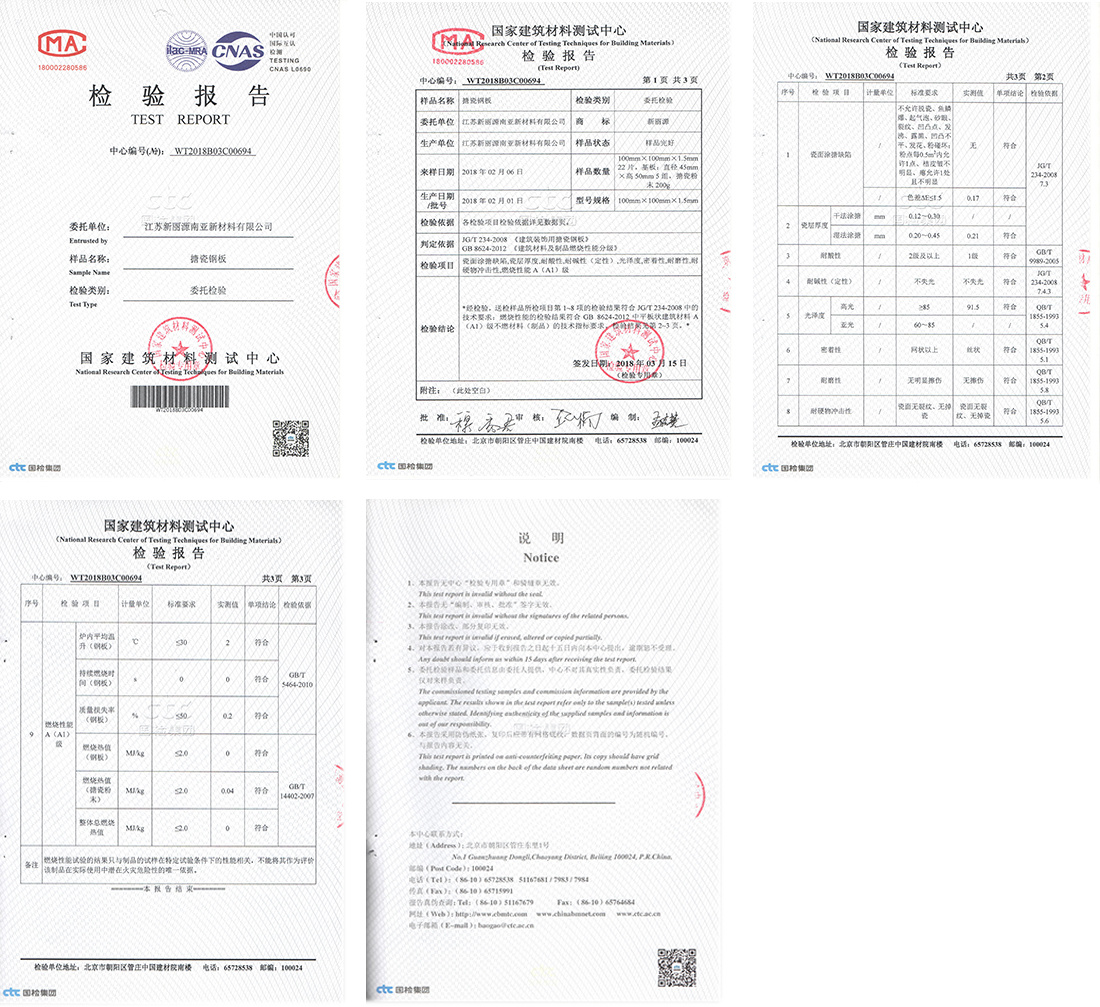

Performance testing

Flame jet Spray the enamel steel plate surface with flame, and the enamel will not be damaged. | Hard object carving After scratching and rubbing with hard objects such as keys, the enamel remains undamaged. | Organic solvent erosion Erosion of the enamel surface with organic solvents results in no damage to the enamel. |

Application

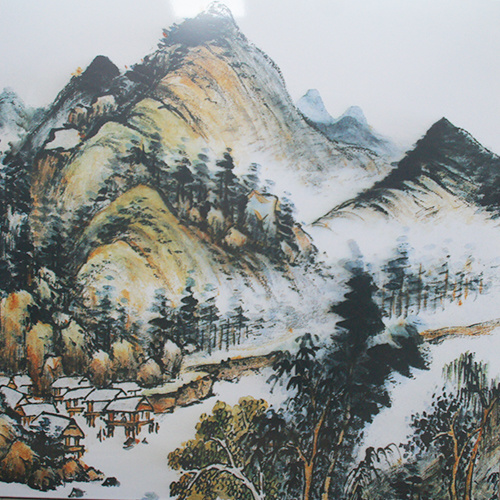

Enamel steel plate blooms with wealth and honor |

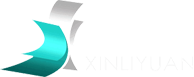

Enamel landscape painting |

Test report

Installation Video

Product application: Hefei Metro Line 3 and Nanjing Tunnel