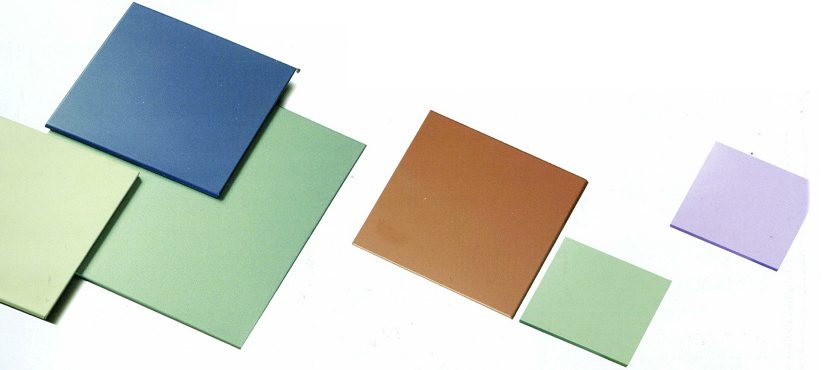

Application scope

Porcelain aluminum panels are widely used for building exterior decoration due to their excellent weather resistance and bright colors. Due to its many advantages such as flame retardancy, corrosion resistance, gas corrosion resistance, pollution resistance, non adhesion, hygiene, and resistance to electromagnetic waves from household appliances, it is commonly used in the manufacturing of kitchen equipment, utensils, kitchen decorative panels, and heating device decorative panels. It can also be used in various pipelines, highway facilities (guardrails, signal lights, signs, etc.), industrial equipment Decorative panels for the interior of public transportation vehicles (buses, subways, airplanes, ships, etc.) in port facilities.

Product Features

1. Pollution resistance: Porcelain aluminum panels possess the water repellency and corrosion resistance of ceramics to various chemical solvents.

2. Excellent economy: able to clean, with good resilience, saving maintenance and management costs. Organic coatings based on fluorocarbon coating expand due to hot weather during the day, causing peeling and cracking of the coating film. When the temperature drops at night, the cracks begin to contract, and during the contraction process, dust and small pollutants take the opportunity to infiltrate and adhere together. The attachment of this pollutant makes it extremely unlikely to recover, thus causing a significant impact on the aesthetics and value of the building. Ceramic coatings that react only at temperatures below -50 ℃ and above 1700 ℃ can prevent the occurrence of peeling, expansion, and shrinkage under such temperature changes. Therefore, even if there are contaminated attachments, they can be easily washed and restored, which means that the cleaning effect can be produced every time it rains.

3. High weather resistance: The coating film of ceramic plates composed of inorganic solvents and pigments has almost no effect of ultraviolet radiation on the ceramic coating film due to its higher bond energy of Si-0 ion bonds than that of ultraviolet radiation. The superiority of its UV resistance makes the porcelain aluminum plate superior in maintaining color and gloss compared to general coatings.

4. Stable structure: Just like rocks or ceramics that will not change after a long period of weathering, the three-dimensional network formed by pure inorganic resin and inorganic pigment in the porcelain coating of porcelain aluminum plates has unique structural stability. It can extend the lifespan of buildings in external environments such as ultraviolet radiation, acid rain, wind, and thermal radiation.

5. Environmental friendliness; Compared to the use of chemical detergents in the pre-treatment of organic coatings, ceramic aluminum panels use sandblasting technology in the early stage, and the ceramic coatings used use water as a dispersant, which will not cause pollution to the air like inorganic coatings volatilized into the air during spraying. Therefore, compared to traditional decorative panels, porcelain aluminum panels are a highly environmentally friendly new decorative material.

6. Excellent heat resistance: The incombustibility of building materials (A1 level), the porcelain coating used for porcelain aluminum panels, composed of inorganic coatings and pigments, has a fire resistance of A1 level, so toxic gases will not be generated due to combustion in a fire.

Application

Hefei Metro Line 3 |

Porcelain printing board |

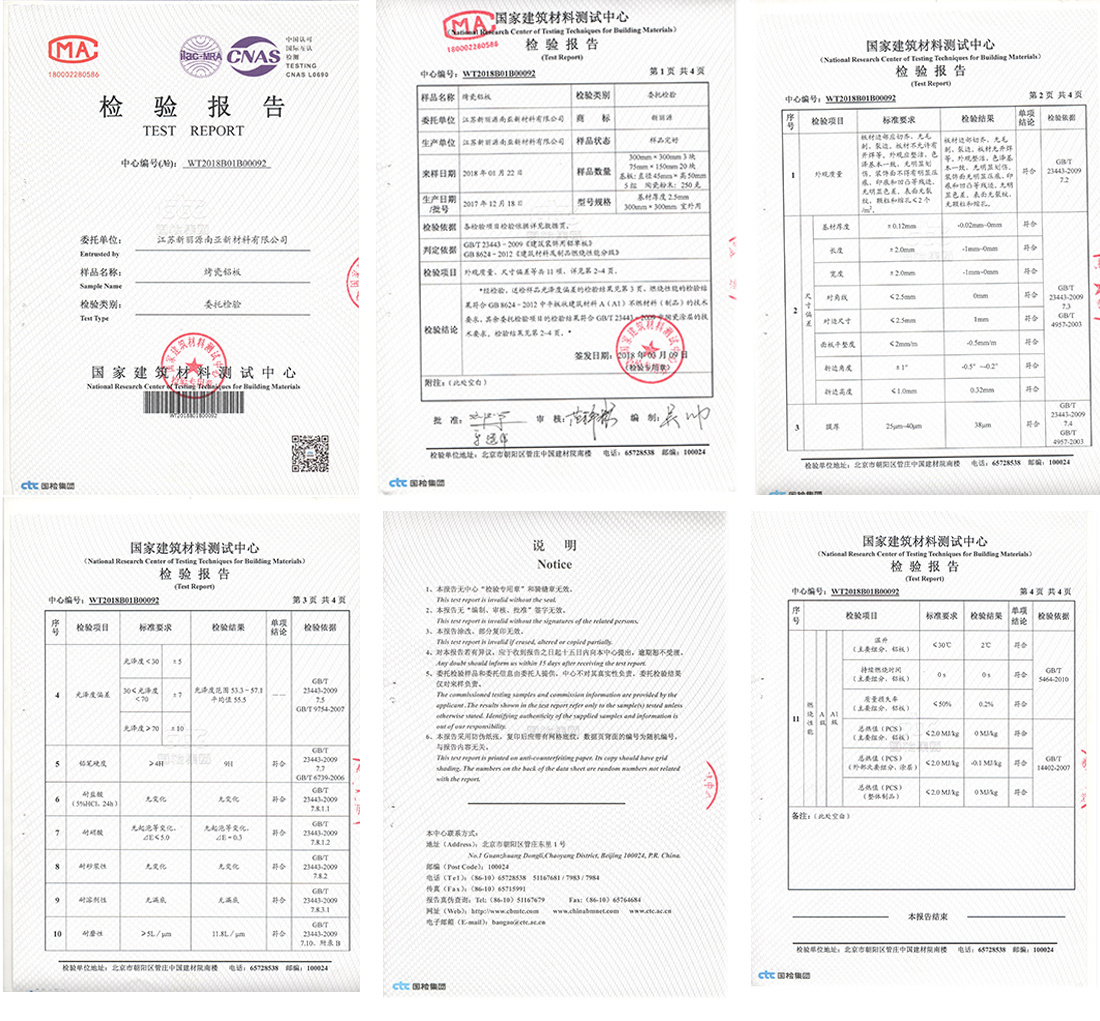

Test report