Product features and structure

Decorative aluminum panels are a universal product for foreign protective structures in today's architecture. It has light weight and high strength; Good weather and corrosion resistance; Strong plasticity and weldability, capable of processing into various beautiful shapes such as flat, curved, and spherical surfaces; Colors can be adjusted according to customer preferences, with a wide range of options and good decorative effects; Good pollution resistance, easy to clean and maintain; The construction and installation are convenient, fast, and recyclable, which is beneficial for environmental protection. Suitable for decorative exterior walls, beams and columns, balconies, partition packaging, suspended ceilings, indoor decoration, etc., it is highly favored by users.

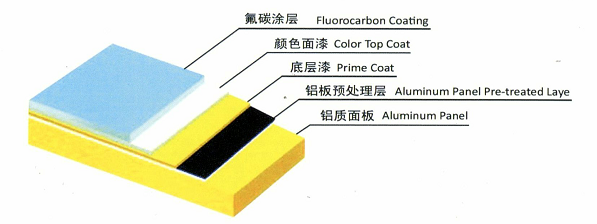

Product production process

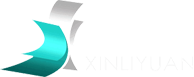

Fluorocarbon aluminum veneer

The application of metal curtain walls worldwide has a history of several decades, and currently there are three types still in use: aluminum veneer, aluminum plastic composite panel, and aluminum honeycomb panel.

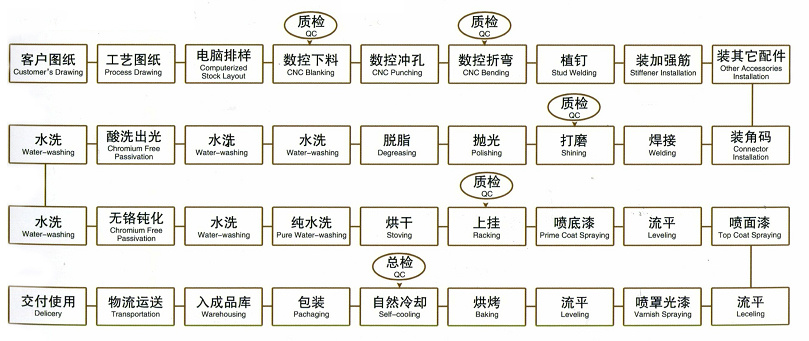

Aluminum veneers generally use 2-4mm thick AA1100 or AA3003 aluminum alloy plates as the substrate, which are formed through CNC folding and other technologies. The surface is sprayed with decorative coatings to meet people's requirements for the appearance color and weather resistance of buildings. Its structure mainly consists of components such as panels, reinforcing ribs, and corner codes. Aluminum veneers can be processed into various shapes and superior performance, making them widely used in buildings.

Material and construction of aluminum veneer

The substrate is made of high-quality high-strength aluminum alloy plates, with thicknesses ranging from 2.0mm, 2.5mm, 3.0mm, 4.0mm, and other specifications.

Its structure mainly consists of components such as panels, reinforcing ribs, and corner codes.

The maximum workpiece size can reach 800mm * 1500mm * 2000mm (L * W * H).

Characteristics of Metal Aluminum Plate

1. Rich in color, it can meet the various color requirements of modern buildings.

2. Can be shaped according to customer requirements, with strong decorative effects.

3. Lightweight, high strength, fast and convenient installation and construction.

4. Effectively prevent ultraviolet ray penetration and greatly increase anti-aging performance.

5. The main component of fluorocarbon polymer coatings is KYNAH50 fluorocarbon resin. This fluorocarbon resin has durable binding force and relatively stable molecular structure, which determines that products treated with fluorocarbon spraying can withstand long-term erosion such as snow and rain, industrial waste gas, and acid rain.

6. Lightning resistance: It can serve as a good conductor of electricity and quickly transmit the huge lightning current to the ground through the building grounding system.

7. Environmental protection: It has strong low pollution and is difficult to adhere pollutants to its surface. It can maintain a smooth and clean appearance for a long time, and is easy to maintain and clean.