|

Background technologyAt present, most of the glass curtain walls used in buildings in China are all aluminum alloy glass curtain walls, which are expensive and have low strength. Moreover, there is no insulation material in the middle of the design, so the heat resistance, sound insulation, and dew resistance functions are poor. Due to the thin aluminum pressure plate, it can only resist small negative wind pressure. In addition, it is easy to fade and not easy to clean, and its surface decoration is poor, which cannot improve the current decorative performance of building curtain walls and lacks market competitiveness. This product is a new type of decorative wall panel with high strength, strong decorative properties, and ice cracking effect. |

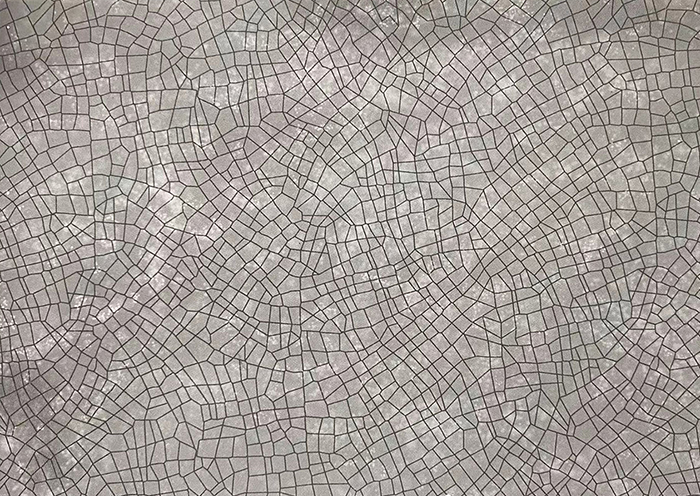

Structure composition diagram explanation

The above diagram is a schematic diagram of an ice cracked enamel steel plate decorative panel, marked with the attached diagram

Bottom lining plate 10, steel plate layer 20, bottom glaze layer 30, top glaze layer 40, cracked porcelain paper 50, anti light film layer 60, honeycomb core plate 70.

Embodiment

The above diagram is a schematic diagram of an ice cracked enamel steel plate decorative panel.

As shown in the figure, an ice cracked enamel steel plate decorative plate includes a bottom lining plate 10, which is provided with multiple sets of hexagonal through holes; A steel plate layer 20 bonded to the upper side of the bottom lining plate 10; Spray the bottom glaze layer 30 on the steel plate layer 20, and spray the top glaze layer 40 on the surface of the bottom glaze layer 30; Cracked porcelain paper 50 transferred to the surface glaze layer 40; And an anti light film layer 60 adhered to the cracked porcelain paper 50.

1. The bottom lining plate 10 is set with a 2mm calcium silicate board, providing environmental support. Due to its superior fire resistance, moisture resistance, and long service life, calcium silicate boards not only have the functions of traditional gypsum boards, but also have been widely used in suspended ceilings and partitions of industrial and commercial engineering buildings, home decoration, furniture lining boards, advertising board lining boards, warehouse ceiling boards, network flooring, and wall panels of indoor engineering such as tunnels. They are widely used. And the bottom lining plate 10 is also equipped with multiple sets of hexagonal through holes, which can effectively absorb sound and reduce weight.

2. The steel plate layer 20 is bonded to the upper side of the bottom lining plate 10 through adhesive, which is selected from the cold rolled steel plate and sprayed with a bottom glaze layer 30 and a top glaze layer 40 on its surface. Among them, glaze is a colorless or colored thin layer of glass covering the surface of ceramic products. It is made by mixing mineral raw materials (feldspar, quartz, talc, kaolin, etc.) with raw materials in a certain proportion (some of which can be made into frits first), grinding and making glaze slurry. It is applied to the surface of the body and calcined at a certain temperature. It can increase the mechanical strength, thermal stability, and dielectric strength of the product, as well as beautify the utensils, facilitate cleaning, and prevent erosion by dust and dirt. In this embodiment, not only can the hardness of the steel plate layer 20 be improved, but it is also scratch resistant, non fading, and insulation weather resistant. In addition, the top glaze layer 40 continues to be sprayed to further enhance performance, rendering the surface artistic and glossy.

3. The top glaze layer 40 should have at least 2 layers, with different colors, selected from inorganic glass materials of different colors, and has a wide range of applications.

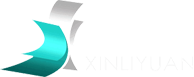

4. Finally, a cracked porcelain paper 50 with ice cracking effect is transferred onto the surface of the enamel layer 40 and sintered at high temperature to form an ice cracking effect on the surface of the enamel steel plate, enhancing its decorative and aesthetic properties.

5. The anti light film layer 60 achieves the anti light property of the enamel steel plate surface and improves its performance. Preferably, the anti light film layer 60 is set as a PVC film layer, which is durable and durable.

6. The surface of the steel plate layer 20 is equipped with a galvanized layer, which can improve stiffness and enhance durability.

7. The honeycomb core plate 70 is fixed on the lower side of the bottom lining plate 10 to further improve the sound absorption and insulation effect.

8. In summary, this product sprays the bottom glaze layer 30 and top glaze layer 40 on the surface of the steel plate layer 20 to form enamel, improve strength and product quality, and then transfers the cracked porcelain paper 50 to form a surface effect of ice cracks, enhance decoration, and improve aesthetics.

The above diagram is a schematic diagram of an ice cracked enamel steel plate decorative panel.

As shown in the figure, an ice cracked enamel steel plate decorative plate includes a bottom lining plate 10, which is provided with multiple sets of hexagonal through holes; A steel plate layer 20 bonded to the upper side of the bottom lining plate 10; Spray the bottom glaze layer 30 on the steel plate layer 20, and spray the top glaze layer 40 on the surface of the bottom glaze layer 30; Cracked porcelain paper 50 transferred to the surface glaze layer 40; And an anti light film layer 60 adhered to the cracked porcelain paper 50.

1. The bottom lining plate 10 is set with a 2mm calcium silicate board, providing environmental support. Due to its superior fire resistance, moisture resistance, and long service life, calcium silicate boards not only have the functions of traditional gypsum boards, but also have been widely used in suspended ceilings and partitions of industrial and commercial engineering buildings, home decoration, furniture lining boards, advertising board lining boards, warehouse ceiling boards, network flooring, and wall panels of indoor engineering such as tunnels. They are widely used. And the bottom lining plate 10 is also equipped with multiple sets of hexagonal through holes, which can effectively absorb sound and reduce weight.

2. The steel plate layer 20 is bonded to the upper side of the bottom lining plate 10 through adhesive, which is selected from the cold rolled steel plate and sprayed with a bottom glaze layer 30 and a top glaze layer 40 on its surface. Among them, glaze is a colorless or colored thin layer of glass covering the surface of ceramic products. It is made by mixing mineral raw materials (feldspar, quartz, talc, kaolin, etc.) with raw materials in a certain proportion (some of which can be made into frits first), grinding and making glaze slurry. It is applied to the surface of the body and calcined at a certain temperature. It can increase the mechanical strength, thermal stability, and dielectric strength of the product, as well as beautify the utensils, facilitate cleaning, and prevent erosion by dust and dirt. In this embodiment, not only can the hardness of the steel plate layer 20 be improved, but it is also scratch resistant, non fading, and insulation weather resistant. In addition, the top glaze layer 40 continues to be sprayed to further enhance performance, rendering the surface artistic and glossy.

3. The top glaze layer 40 should have at least 2 layers, with different colors, selected from inorganic glass materials of different colors, and has a wide range of applications.

4. Finally, a cracked porcelain paper 50 with ice cracking effect is transferred onto the surface of the enamel layer 40 and sintered at high temperature to form an ice cracking effect on the surface of the enamel steel plate, enhancing its decorative and aesthetic properties.

5. The anti light film layer 60 achieves the anti light property of the enamel steel plate surface and improves its performance. Preferably, the anti light film layer 60 is set as a PVC film layer, which is durable and durable.

6. The surface of the steel plate layer 20 is equipped with a galvanized layer, which can improve stiffness and enhance durability.

7. The honeycomb core plate 70 is fixed on the lower side of the bottom lining plate 10 to further improve the sound absorption and insulation effect.

8. In summary, this product sprays the bottom glaze layer 30 and top glaze layer 40 on the surface of the steel plate layer 20 to form enamel, improve strength and product quality, and then transfers the cracked porcelain paper 50 to form a surface effect of ice cracks, enhance decoration, and improve aesthetics.

Technical implementation elements

1. This product is an ice cracked enamel steel plate decorative panel, used to avoid the troubles of low strength, poor surface performance, and poor decorative performance of decorative curtain wall panels in the past;

2. In order to solve the above technical problems, multiple sets of hexagonal through-holes are set up on the bottom lining plate of this product;

3. A steel plate layer bonded to the upper side of the bottom lining plate;

4. The bottom glaze layer sprayed on the steel plate layer, and the surface of the bottom glaze layer is sprayed with a top glaze layer;

5. Cracked porcelain paper transferred to the surface glaze layer;

6. And an anti light film layer adhered to cracked porcelain paper;

7. The bottom lining plate is set with a 2mm calcium silicate board;

8. The surface of the above-mentioned steel plate layer is equipped with a galvanized layer;

9. Among them, at least 2 layers of the above surface glaze layer are set, and the colors are different;

10. The honeycomb core plate is fixed on the lower side of the bottom lining plate;

11. The above anti light film layer is set as a PVC film layer;

12. By spraying a bottom and top glaze layer on the surface of the steel plate layer, enamel is formed to improve strength and product quality. Then, cracked porcelain paper is transferred to form a surface effect of ice cracks, enhance decoration, and improve aesthetics.

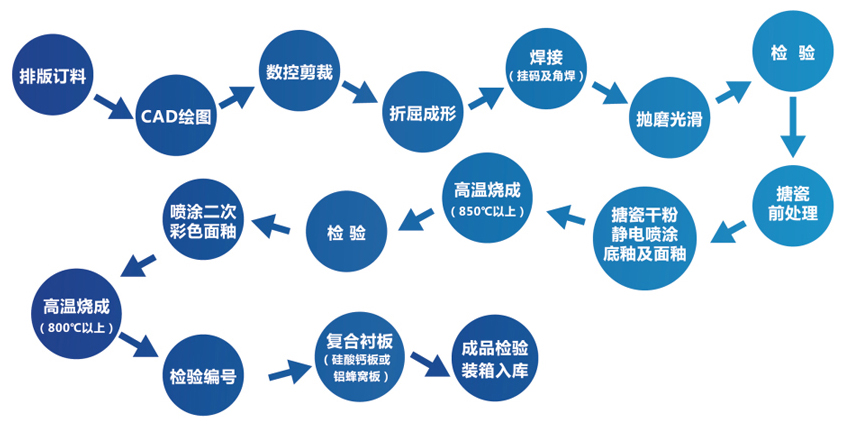

Technological process

Performance testing

Flame jet

Spray the enamel steel plate surface with flame, and the enamel will not be damaged. |

Hard object carving

After scratching and rubbing with hard objects such as keys, the enamel remains undamaged. |

Organic solvent erosion

Erosion of the enamel surface with organic solvents results in no damage to the enamel. |

Patent certificate